ADDITIVE MANUFACTURING IN DEFENCE

Additive Manufacturing technologies are used throughout the British Army and the US Armed Forces to create critical parts, tools, fixes and more, when and where it's needed most.

Be ready for any challenges, with robust, reliable and secure 3D printers and software.

AREAS OF APPLICATION

REPAIRS IN FIELD

Print parts on demand, from anywhere in the world, for spare parts and repairs whenever and wherever they are needed.

PROTOTYPING

Dramatically shorten prototype production times, from weeks to hours, and unlock full design freedom.

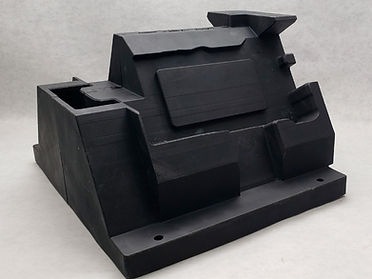

BESPOKE TOOLING

Produce strong, lightweight, better performing tooling, jigs and fixtures, at less time and cost, to aid manufacture and assembly across production lines.

TEMPORARY FIXES

Fix equipment in the field by 3D printing bespoke parts on demand, with secure, offline options available.

Want to learn more?

The Markforged X7 Field Edition is the rugged, field-deployable industrial 3D printer for tactical response to supply challenges in remote locations.

Rapid Prototyping for Mission-Critical Markets

Motorola Solutions uses Nexa3D NXE400 3D printers for the design and development of highly sophisticated communications devices for professional and mission-critical markets in the commercial, government and industrial segments.

Being able to design, prototype and test parts inhouse have given Motorola Solutions a significant advantage in time and cost savings.

Since integrating the NXE 400 into their process, the team has found that they were able to print 5 to 10 times the speed of their traditional SLA machines.

3D Printing Indispensable for the United States Army

By using Markforged Additive Manufacturing technology, the United States Army is able to create readiness factors that decrease downtime.

The US Army's Markforged Composite and Metal 3D printers have been used for personal protective equipment (PPE), window wiper brackets for military vehicles, tools, and low-volume production parts.

The ability to 3D print a critical low-volume replacement part for a component that is no longer available saved one regiment $244,000.